EA-33NF-SN-EXT

This product is already in your quote request list.

Overview

Overview

Features & Specifications

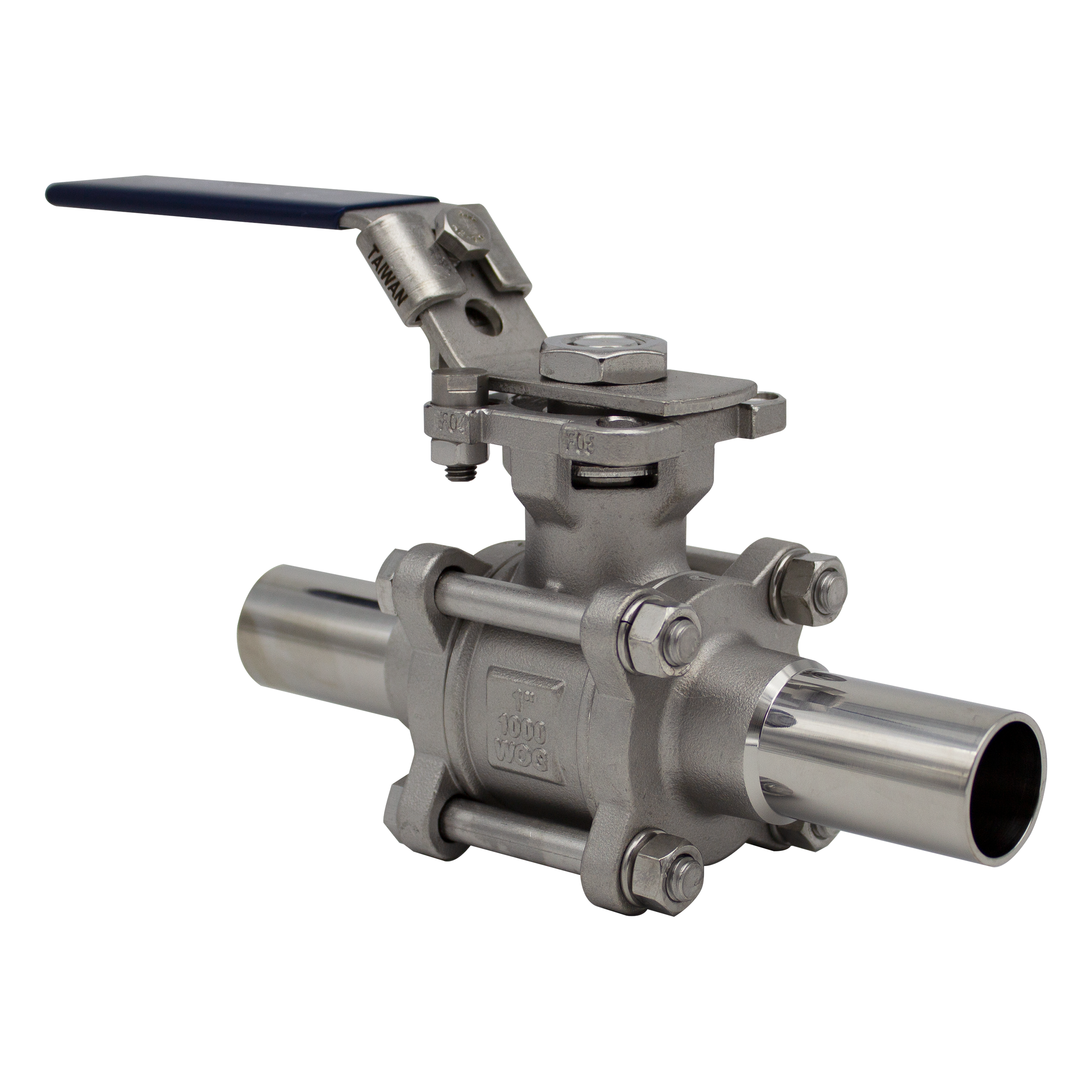

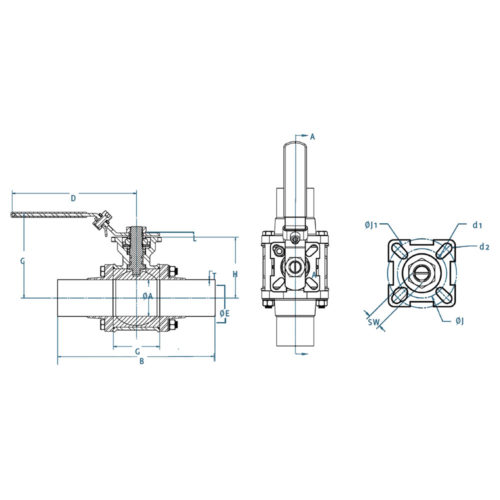

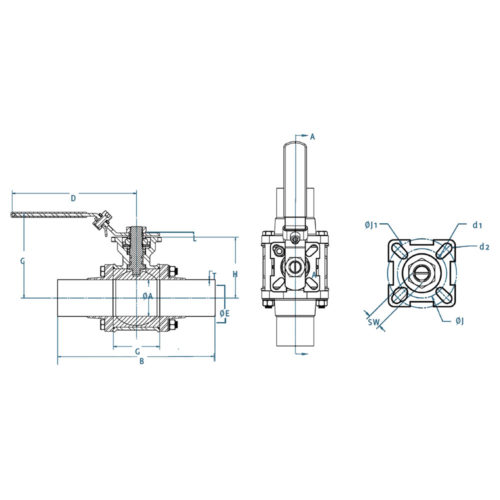

- ASTM 316/316L stainless steel; 316L extended butt-weld ends allow inline welding without disassembly of valve, suitable for orbital welding

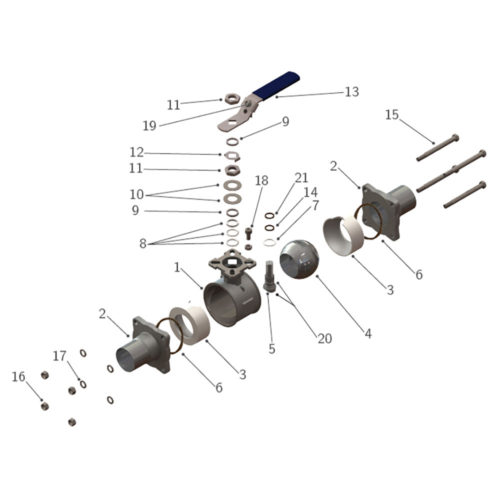

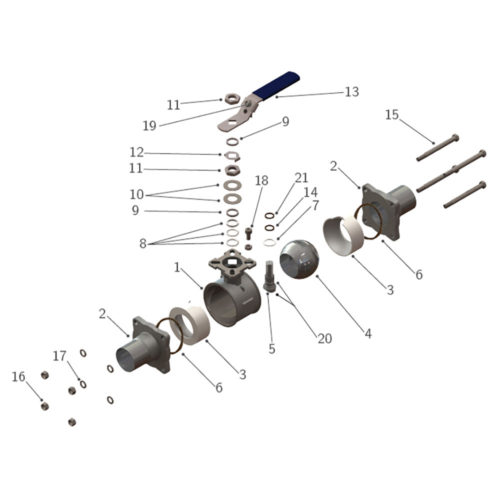

- 3-PC body design facilities inspection and easy inline repair

- Full port flow to tube ID without tapering

- Highly polished 8-12 Ra ID

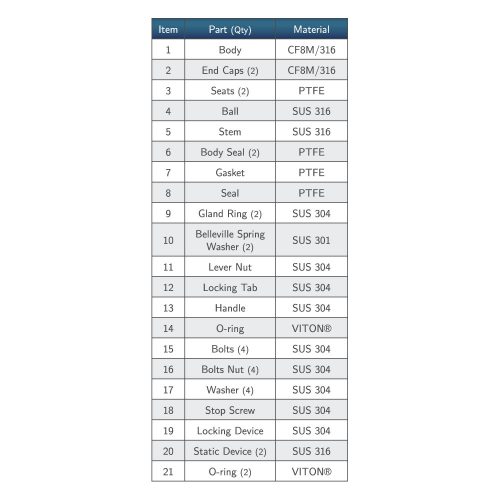

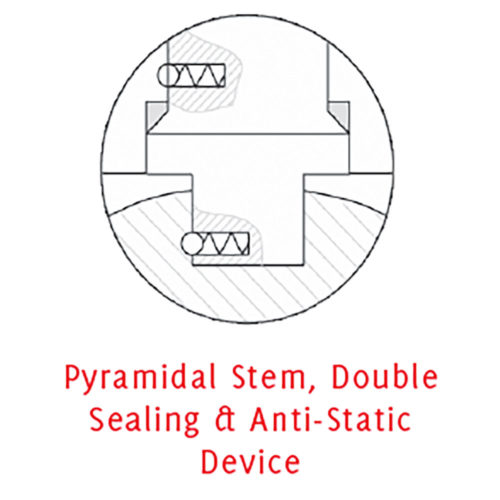

- Live loaded, self-adjusting packing and Belleville washers provide better sealing and defense against leaking

- 3-PC, v-ring stem packing for superior sealing and lower torque

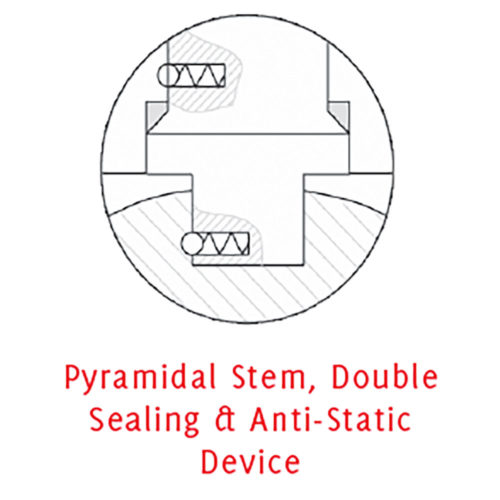

- Blowout-proof, bottom entry stem design and anti-static device

- ANSI B16/B2/B18, MSS-SP82, NSF 61 AWWA

- Using body cavity fillers meets FDA, USDA & 3A requirements

- Designed for high cycle automated applications

- 100% tested and inspected prior to shipping

- Full traceability of all components

- SST x PTFE seats available for high temperature applications

- Available in regular or cavity filled styles

- Standard seats are TFM-1600

- Cavity fillers are virgin PTFE-meets CFR21

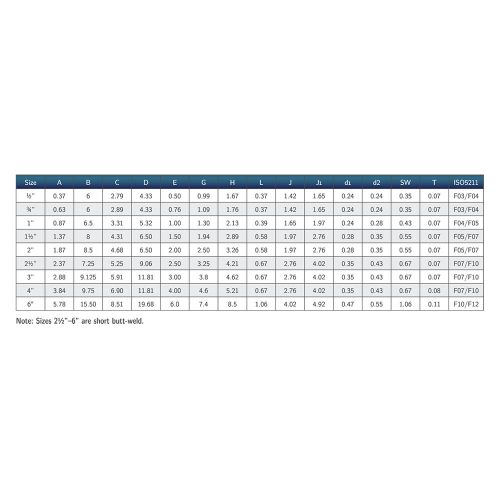

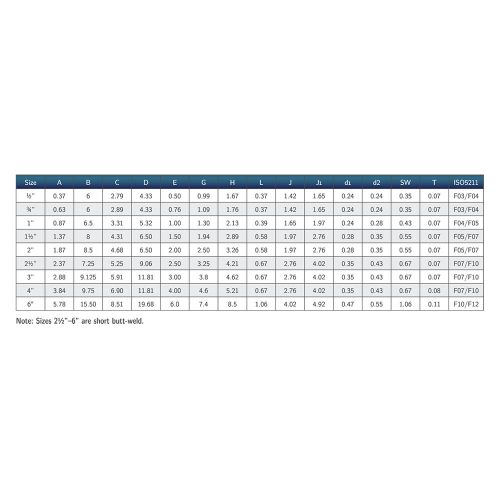

- Sizes ½”–2″ in 316L extended tube design

- 2½”–6″ available in short butt-weld design

- Cavity Filled Are suitable for up to 50% vacuum applications

- ½”-2″ have 4 bolts, 2½”-6″ have 6 bolts

Catalog Page

Tech Info

Tech Info

Click on an image to see a full size rendering.

Resources